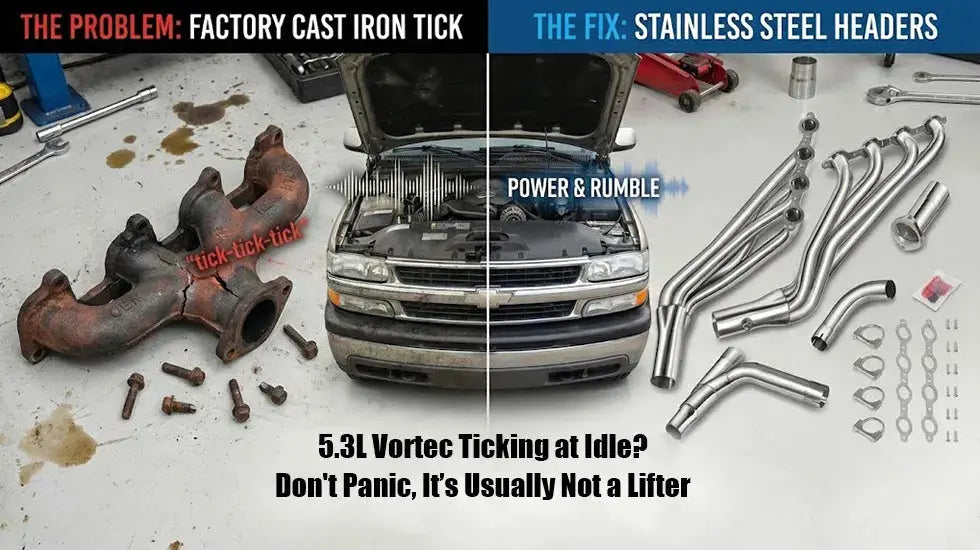

If your 1999–2006 Silverado or Sierra sounds like a diesel tractor at a red light, I know exactly what you’re thinking: "There goes my lifter, time for an engine rebuild." Slow down. In my 15 years turning wrenches on the GMT800 platform, 9 out of 10 "ticks" I diagnose aren't internal—they're broken exhaust manifold bolts.

- The Cold Start Test: Does the tick fade after the engine warms up (5-10 mins)? If yes, it’s 100% an exhaust leak. Metal expands with heat and seals the gap.

- The Visual Check: Grab a flashlight. Look at the rear-most bolt on the driver’s side (Cylinder #7) or the front-most on the passenger side (Cylinder #2). If the bolt head is missing, you’ve found your culprit.

The Engineering Failure: Aluminum vs. Cast Iron

The 5.3L (LM7/L59) uses aluminum heads and heavy cast iron "log" manifolds. These materials have vastly different thermal expansion coefficients. Aluminum grows faster than iron when hot. Every heat cycle puts the M8x1.25 steel bolts in a literal "tug-of-war." Eventually, the bolt—usually the one at the back where heat stays trapped—snaps off flush with the head.

I remember a guy in '19 brought in an 04 Tahoe. A chain shop quoted him $2,500 for a "collapsed lifter" job. I pulled the inner fender liner, showed him the carbon soot (black staining) around the rear exhaust port, and snapped a photo of the missing bolt head. We didn't touch the valvetrain. We installed headers, and the truck was silent. Always check for soot on the head before buying lifters.

Why "Stock" Repairs Fail (The Dealer Trap)

Most dealers will charge you $800+ to extract the bolt and put a new Dorman or OEM cast iron manifold back on. Don’t do it. You are re-installing the same thermal stress problem. In my experience, a new cast iron manifold on a truck that tows will warp and snap a bolt again within 30k to 50k miles.

The 3 Fixes (Choose Your Budget):

- The "Band-Aid" ($30): Bolt-on repair clamps (like the KAP169). They use an existing bracket hole to apply pressure to the manifold. Great for a quick fix, but it doesn't solve the flow restriction.

- The "Standard" ($150): Extract the bolts and replace with Grade 10.9 hardware. Warning: If you aren't comfortable welding a nut to a broken stud, don't try this at home.

- The "Permanent Fix" ($350+): Upgrade to Stainless Steel exhaust headers. This eliminates the cast iron entirely.

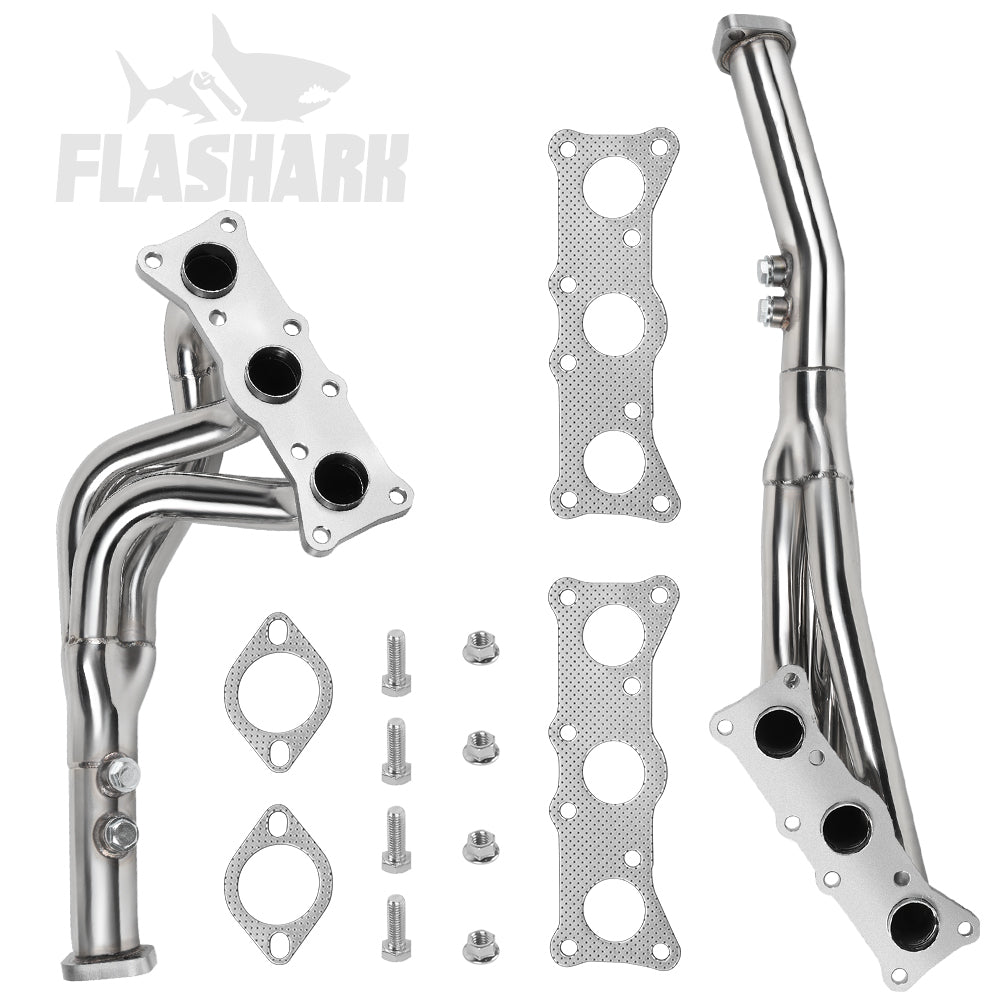

The Expert Solution: Flashark Long Tube Headers

If you have to pull the manifold anyway, why put the restrictive "logs" back on? My go-to recommendation for this platform is the Flashark Long Tube Headers for 1999-2006 Chevy Silverado 1500 5.3L Vortec. Upgrading to T304 Stainless solves the thermal issue because the thin-walled tubing dissipates heat faster and "gives" more than brittle cast iron.

I see guys on forums recommending the cheap paper gaskets that come in some kits. Don't do it. I’ve had to redo dozens of jobs because those blow out in six months. I only use GM Original Equipment Multi-Layer Steel (MLS) gaskets (Part #12617944). They are the only thing that actually seals an LS head long-term.

Performance Gains (Data-Backed)

Beyond the silence, you’re looking at a legitimate bump in power. On a stock 5.3L with a mild tune, these headers typically pick up:

| Metric | Stock Manifold | Flashark Long Tubes |

|---|---|---|

| Horsepower | Baseline | +18 to +25 whp |

| Torque | Restricted | +20 lb-ft (Mid-range) |

| Heat Dissipation | Poor (Heat Soaks) | Excellent (Stainless) |

Wrenching Guide: GMT800 Specific Tips

Installing these on a Silverado/Sierra is straightforward, but there are three things that will annoy you if you aren't prepared:

- The Dipstick Tube: You will have to fight the oil dipstick tube. Remove the 15mm bolt holding it to the head, pull the tube out (replace the O-ring while you're there!), and gently bend it to clear the new primary tubes once the headers are in.

- Steering Shaft: If the header touches the steering shaft, your motor mounts are likely shot and the engine is sagging. Replace the mounts rather than "clearancing" the header with a hammer.

- Spark Plugs: Pull your plugs before you start. It takes 5 minutes and prevents you from cracking a porcelain insulator when you’re wrestling the heavy iron manifolds out.

Final Verdict

Stop driving a truck that sounds broken. If you have a ticking 5.3L, verify it's the exhaust, ditch the cast iron, and get some stainless steel on there. You’ll get a better sound, more towing torque, and you'll never have to drill out a snapped manifold bolt again.

👨🔧 Ask the Mechanic: Critical FAQ

• If you have a 2003-2006: You don't need EGR provisions.

• If you have a 1999-2002: You have two choices: buy headers with an EGR bung (harder to find) or buy the standard headers and use an EGR Block-off Plate (and delete the code in the ECU tune). Most of my customers just delete it to clean up the engine bay.

• If you live in California (CARB states): These are strictly for "Off-Road Use Only." You will fail visual inspection.

• If you live in a state with only OBDII plug-in tests: As long as you have high-flow cats welded in and a good tune (no Check Engine Light), many guys pass. But legally? They are for off-road use.