Los colectores de escape son componentes vitales de los motores de combustión interna, ya que desempeñan un papel fundamental en la conducción de los gases de escape desde los cilindros hasta el sistema de escape. Durante este proceso, los gases de escape alcanzan temperaturas increíblemente altas que, si no se gestionan adecuadamente, pueden afectar el rendimiento del motor y la vida útil de los componentes.

Para propietarios de vehículos, fabricantes de motores o entusiastas de la automoción, comprender la temperatura de los colectores de escape es crucial. Esto no solo influye en el rendimiento del vehículo, sino que también afecta la vida útil tanto del sistema de escape como del motor. En este artículo, exploraremos los factores que afectan la temperatura de los colectores de escape, los rangos de temperatura típicos que se pueden esperar y estrategias efectivas para controlar el calor. Ya sea que busque optimizar el rendimiento o simplemente proteger su vehículo de daños causados por el calor, comprender la temperatura de los escapes es fundamental.

¿Qué son los colectores de escape?

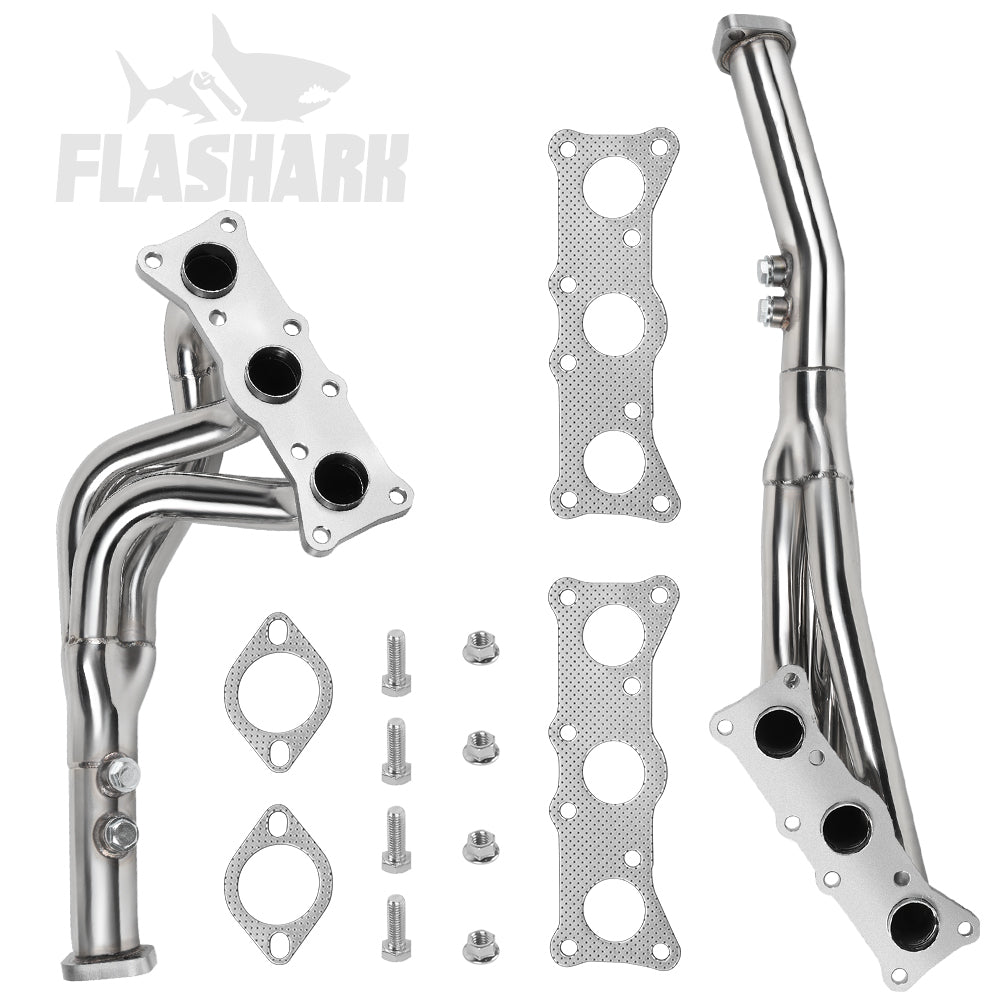

Los colectores de escape son componentes integrales del sistema de escape que dirigen los gases de escape desde los cilindros del motor hacia el resto del sistema. Al mejorar el flujo de escape, reducen la contrapresión y mejoran la eficiencia del motor. En resumen, ayudan a expulsar los gases de escape de forma rápida y suave, lo que puede mejorar el rendimiento.

Generalmente fabricados con materiales como acero inoxidable, hierro fundido o titanio, la elección del material juega un papel crucial en la capacidad de los colectores de escape de alto rendimiento para soportar y gestionar las altas temperaturas producidas por el motor. Comprender la función y las propiedades del material de los colectores de escape es el primer paso para comprender el calor que pueden generar, lo cual afecta directamente el rendimiento y la seguridad del vehículo.

Factores que afectan la temperatura del colector de escape

La temperatura del colector de escape puede variar significativamente según diversos factores. El calor generado por el sistema de escape se ve influenciado por el tipo de motor, las condiciones de conducción y el diseño del propio sistema de escape. Profundicemos en estos elementos clave.

Tipo de motor y su impacto

Los diferentes tipos de motores producen distintos niveles de calor durante su funcionamiento. Por ejemplo, los motores de aspiración natural, que dependen de la presión atmosférica para aspirar el aire, suelen generar menos calor de escape que los motores de inducción forzada (turboalimentados o sobrealimentados). Los motores turboalimentados, por ejemplo, introducen aire a presión en los cilindros, lo que genera calor adicional en el proceso de combustión, lo que aumenta directamente la temperatura del escape.

Además, el nivel de rendimiento de un motor influye en la temperatura de escape. Los motores de alto rendimiento, como los de los autos deportivos o de carreras, generan temperaturas de escape significativamente más altas. Estos motores funcionan a mayores RPM y consumen más combustible, lo que genera más calor en el sistema de escape.

Condiciones de conducción y sus efectos

Las condiciones de conducción de un vehículo también influyen considerablemente en la temperatura del colector de escape. La conducción agresiva, como la aceleración rápida, la conducción a alta velocidad o las condiciones de carga pesada, aumenta la potencia del motor y, en consecuencia, la temperatura del escape. Por el contrario, conducir en condiciones normales, como circular a velocidad constante en autopista, generalmente resulta en temperaturas de escape más bajas.

Por ejemplo, remolcar una carga pesada o subir pendientes pronunciadas requiere más potencia del motor, lo que provoca temperaturas de escape más altas. El esfuerzo adicional que soporta el motor en estas condiciones genera más calor, lo que puede sobrecargar el sistema de escape con el tiempo.

Diseño del sistema de escape

El diseño del sistema de escape también puede influir en la gestión térmica de los colectores. Los sistemas de escape de alto rendimiento suelen incluir colectores o tubos más grandes, diseñados para reducir la contrapresión y mejorar el flujo de escape. Si bien estos sistemas pueden optimizar el rendimiento del motor, también pueden contribuir a temperaturas de escape más altas debido al mayor volumen de gases de escape que circulan por el sistema.

La elección del material juega un papel importante en la gestión del calor de un sistema de escape. El acero inoxidable, por ejemplo, ofrece una buena resistencia al calor, mientras que el titanio proporciona propiedades térmicas superiores que permiten al sistema soportar temperaturas más altas. El diámetro y la longitud de los tubos de escape también influyen en la disipación del calor, lo que influye en la temperatura general del sistema.

Rango de temperatura típico para colectores de escape

Comprender el rango típico de temperatura de los colectores de escape es esencial para supervisar y gestionar el estado del motor. Las temperaturas de escape pueden variar considerablemente según las condiciones de conducción y el rendimiento del motor, pero existen rangos de temperatura estándar dentro de los cuales se encuentran la mayoría de los vehículos.

Rango de temperatura de funcionamiento estándar

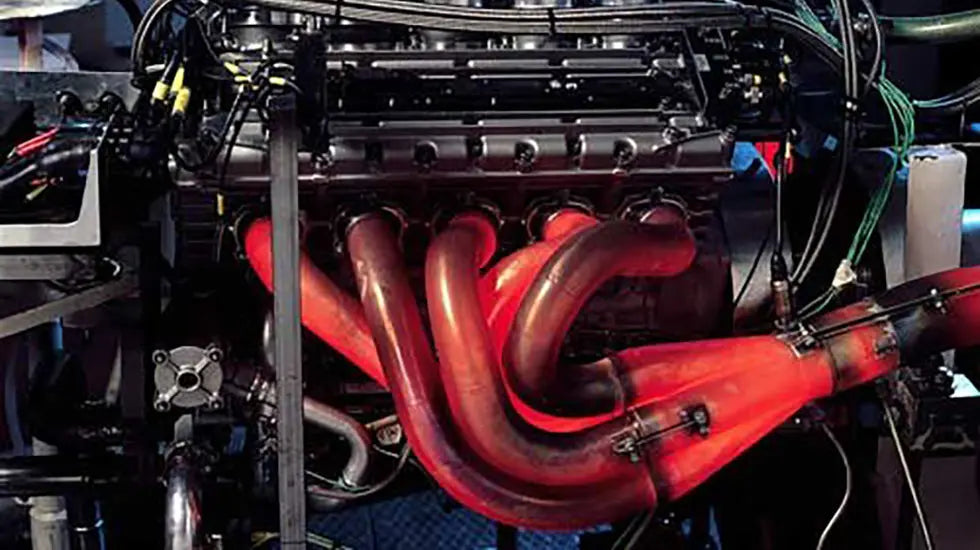

En condiciones normales de conducción, la temperatura de los colectores de escape suele oscilar entre 600 °C y 1000 °C (aproximadamente entre 1100 °F y 1800 °F). Estos valores representan las temperaturas de escape típicas en condiciones de conducción estable para la mayoría de los motores de aspiración natural o de serie. Sin embargo, en vehículos con sistemas de escape modificados o motores turboalimentados, estas temperaturas pueden superar este rango.

Los vehículos de alto rendimiento o los utilizados en carreras pueden experimentar temperaturas de escape muy superiores a los 1000 °C debido a su mayor potencia y a sus estilos de conducción más agresivos. Por ello, comprender y gestionar estas temperaturas es fundamental para evitar daños a largo plazo.

Variaciones de temperatura en diferentes condiciones

Las temperaturas de escape son dinámicas y fluctúan en función de diversos factores. Por ejemplo, cuando un motor está sometido a alta carga o acelera, los gases de escape se calientan más. En estos casos, la temperatura de escape puede superar fácilmente los 1000 °C, llegando en ocasiones a los 1200 °C o más en configuraciones de alto rendimiento.

Por el contrario, en condiciones de baja carga, como al circular por carretera o al ralentí, las temperaturas del escape se mantienen relativamente estables y bajas, generalmente entre 600 °C y 800 °C. Es importante que los propietarios de vehículos y los entusiastas del alto rendimiento comprendan cómo sus condiciones de conducción afectan las temperaturas del escape para evitar el sobrecalentamiento u otros problemas relacionados.

Motores de alto rendimiento y modificados

Cuando se modifica un motor para mejorar su rendimiento, como añadir turbocompresores o aumentar la relación de compresión, el sistema de escape se somete a temperaturas significativamente más altas. Este aumento de calor se debe a que el motor produce más potencia para optimizar el rendimiento. Por ejemplo, los motores turboalimentados no solo aumentan el volumen de los gases de escape, sino que también generan más calor debido a la naturaleza del proceso de turboalimentación.

En estos casos, controlar las altas temperaturas del escape se vuelve esencial. Si el sistema de escape no está diseñado para soportar estas temperaturas más altas, puede provocar la degradación prematura del material o su fallo.

Consecuencias del calor excesivo en los colectores de escape

El calor excesivo puede provocar numerosos problemas en el sistema de escape, afectando tanto el rendimiento como la seguridad. Las consecuencias más comunes de las altas temperaturas en el escape incluyen la degradación del material, la pérdida de eficiencia del motor y posibles riesgos de seguridad.

Degradación del material

El calor excesivo puede deteriorar con el tiempo los materiales de los colectores de escape. Metales como el acero inoxidable y el hierro fundido pueden volverse quebradizos, oxidarse y, con el tiempo, agrietarse con la exposición prolongada a altas temperaturas. Esta degradación no solo afecta la integridad de los colectores de escape, sino que también puede ocasionar costosas reparaciones o reemplazos.

Impacto en el rendimiento del motor

Las altas temperaturas del escape también pueden afectar negativamente el rendimiento del motor. El calor excesivo puede causar detonación (detonación) o preignición, lo que puede provocar pérdida de potencia, menor eficiencia del combustible e incluso daños en el motor. Además, componentes como los turbocompresores pueden experimentar sobrecarga térmica, lo que puede provocar una disminución del rendimiento o fallos.

Riesgos de seguridad y peligros de incendio

Otro riesgo importante asociado con las altas temperaturas de escape es la posibilidad de incendio. A medida que los sistemas de escape se calientan, los materiales circundantes, como cables, mangueras o incluso líneas de combustible, pueden acercarse peligrosamente a sus puntos de ignición. Si el calor no se controla adecuadamente, esto puede provocar riesgos de incendio y graves problemas de seguridad.

Cómo gestionar las altas temperaturas en los sistemas de escape

Una gestión eficaz del calor es crucial para prevenir daños y optimizar el rendimiento del vehículo. Existen diversos métodos y tecnologías disponibles para ayudar a gestionar y reducir el calor generado por los sistemas de escape.

Envolturas térmicas y materiales de aislamiento

Uno de los métodos más populares para controlar la temperatura del escape es el uso de envolturas térmicas. Estas envolturas están hechas de materiales como fibra de vidrio o basalto y están diseñadas para envolver los colectores y tubos de escape. Estas envolturas ayudan a contener el calor dentro del sistema de escape, reduciendo la cantidad de calor que se irradia al exterior. De esta manera, protegen los componentes circundantes del motor y pueden mejorar el flujo de escape al mantener altas las temperaturas de los gases de escape para una mejor velocidad.

Sin embargo, las envolturas térmicas deben usarse con cuidado. Si retienen la humedad o no reciben el mantenimiento adecuado, pueden provocar oxidación y desgaste prematuro de los cabezales. Para un rendimiento óptimo, se requieren inspecciones y mantenimiento regulares.

Recubrimientos cerámicos y sus beneficios

Los recubrimientos cerámicos son otro método muy eficaz para controlar la temperatura del escape. Estos recubrimientos se aplican a los colectores de escape para crear una barrera térmica que refleja el calor fuera del compartimento del motor. No solo ayudan a controlar la temperatura, sino que también ofrecen ventajas adicionales, como la resistencia a la corrosión, que prolonga la vida útil de los componentes del escape.

Los recubrimientos cerámicos pueden mejorar significativamente la eficiencia del sistema de escape al mantener los gases de escape más calientes durante períodos más largos, lo que les permite fluir más libremente a través del sistema y mejorar el rendimiento del motor.

Actualizaciones del sistema de escape

Mejorar el sistema de escape es una solución a largo plazo para gestionar temperaturas más altas. Los colectores de acero inoxidable, por ejemplo, soportan más calor que los de serie, mientras que los sistemas de escape de titanio son aún más duraderos en condiciones de alta temperatura. Invertir en sistemas de escape de alto rendimiento diseñados para soportar altas temperaturas es esencial para vehículos que experimentan condiciones de conducción extremas, como carreras o todoterreno.

Además de utilizar mejores materiales, la actualización a tubos de escape de mayor diámetro y la optimización de la longitud de los colectores pueden ayudar a reducir la cantidad de calor retenido en el sistema, disminuyendo así el riesgo de sobrecalentamiento.

Señales de sobrecalentamiento: Cómo identificar cuándo los colectores de escape están demasiado calientes

También puedes controlar las temperaturas de escape buscando señales de sobrecalentamiento:

-

Ruido inusual en el sistema de escape : si escucha ruidos de estallidos o traqueteos, podría indicar que el sistema de escape está bajo tensión debido al calor excesivo.

-

Decoloración de los tubos de escape : Un cambio en el color de los tubos de escape, como tonos azules o morados, es una señal común de que las temperaturas son demasiado altas.

-

Olor a quemado : el sobrecalentamiento puede provocar un olor a quemado a medida que los materiales del sistema de escape se descomponen.

-

Pérdida de potencia o falla de encendido del motor : el calor excesivo puede provocar contrapresión que reduce la potencia del motor o provoca fallas de encendido.

-

Grietas o daños visibles : el sobrecalentamiento prolongado puede provocar grietas o deformaciones en el sistema de escape.

Conclusión: Cómo mantener los colectores de escape en óptimas condiciones

Controlar la temperatura de los colectores de escape es esencial para garantizar el rendimiento y la longevidad del motor. Al comprender los factores que afectan la temperatura del escape y utilizar técnicas como envolturas térmicas, recubrimientos cerámicos y la actualización a sistemas de escape de alto rendimiento, puede proteger eficazmente su sistema de escape y optimizar la eficiencia del motor. Monitorear regularmente la temperatura del escape y estar atento a las señales de sobrecalentamiento también le ayudará a identificar posibles problemas a tiempo y a evitar reparaciones costosas. Con el cuidado y el mantenimiento adecuados, puede mantener sus colectores de escape en óptimas condiciones y garantizar que su vehículo siga rindiendo al máximo.