Choosing the best headers for a 5.9 Magnum engine is one of the most effective ways to improve performance without internal engine modifications. For Dodge Magnum V8 owners, headers directly influence horsepower, torque, throttle response, and exhaust efficiency.

This guide explains how exhaust headers work on the 5.9 Magnum platform, what design factors matter most, and how a properly engineered header upgrade delivers measurable results.

Understanding the 5.9 Magnum V8 Engine Platform

The 5.9L Magnum V8 is a naturally aspirated pushrod engine designed for durability and strong low-end torque. From the factory, it uses cast iron exhaust manifolds that prioritize cost control and emissions compliance over airflow efficiency.

According to internal combustion engine airflow studies, restrictive exhaust manifolds are a primary bottleneck in naturally aspirated V8 performance, making the 5.9 Magnum highly responsive to exhaust upgrades.

Why Headers Matter on a 5.9 Magnum Engine

On the 5.9 Magnum, exhaust headers significantly enhance engine performance by improving the evacuation of exhaust gases. Factory exhaust manifolds create backpressure and limit flow, which restricts power output.

Headers are designed to optimize exhaust scavenging by using tuned-length tubes. This reduces the residual exhaust in the cylinder, which allows for more efficient combustion on the next cycle.

For a naturally aspirated engine like the 5.9 Magnum, these improvements translate into better throttle response, more torque, and increased horsepower across the usable RPM range. Whether you’re accelerating on the highway or towing, upgrading to headers will provide a noticeable difference in engine efficiency.

Long Tube vs Short Tube Headers for 5.9 Magnum

The choice between long tube and short tube headers comes down to performance goals and vehicle layout.

Long tube headers are designed for maximum performance, with longer primary tubes that enhance exhaust pulse timing and scavenging efficiency. This results in higher mid-range and top-end horsepower, making them ideal for high-RPM use.

Short tube headers are more compact and easier to install, but their performance gains are limited compared to long tube designs. While they reduce some backpressure, their impact on low- to mid-range power is less pronounced.

For the 5.9 Magnum, long tube headers are generally the better choice, offering more consistent power gains across a wider RPM range, especially when the vehicle is used for towing or spirited driving.

Key Factors to Consider When Choosing the Best Headers for 5.9 Magnum

Choosing the best headers for a 5.9 Magnum requires more than selecting a part that simply bolts on. Header design must align with the engine’s airflow characteristics, exhaust velocity requirements, and vehicle configuration.

Exhaust system engineering principles and naturally aspirated V8 development research consistently show that correct sizing, length, and material selection directly affect torque delivery, horsepower potential, and long-term reliability.

-

Engine Displacement Compatibility

The 5.9 Magnum relies on exhaust gas velocity for effective scavenging. Headers must be sized specifically for this displacement to preserve torque and throttle response. -

Primary Tube Diameter

Moderate primary tube sizing maintains exhaust pulse energy and delivers balanced low- and mid-range performance for street-driven Magnum engines. -

Header Length and Powerband Behavior

Longer header designs typically improve mid-range and upper-RPM output by optimizing exhaust pulse timing when installation space allows. -

Collector and Outlet Design

Properly sized collectors reduce turbulence and support smooth pressure recovery, which is critical for consistent exhaust flow. -

Vehicle Configuration and Fitment

Chassis layout and drivetrain configuration, especially 2WD versus 4WD, directly determine header compatibility and installation feasibility. -

EGR and Emissions Configuration

Header selection must match the engine’s emissions setup to avoid fitment conflicts and maintain system reliability. -

Material and Thermal Resistance

Stainless steel construction offers superior durability, corrosion resistance, and stability under repeated heat cycles. -

Flange Thickness and Sealing Reliability

Thicker flanges improve sealing performance and reduce the risk of warping or exhaust leaks over time. -

Installation Practicality

The best headers deliver measurable performance gains without introducing unnecessary installation complexity or maintenance concerns.

Recommended Header Design for 5.9 Magnum Applications

For a naturally aspirated 5.9 Magnum V8, optimal header design focuses on maintaining exhaust velocity while reducing backpressure. Oversized tubing can reduce low-end torque, while undersized tubing restricts airflow.

Performance exhaust development guidelines consistently show that balanced tube sizing and smooth collectors provide the best combination of power, drivability, and efficiency for Magnum engines.

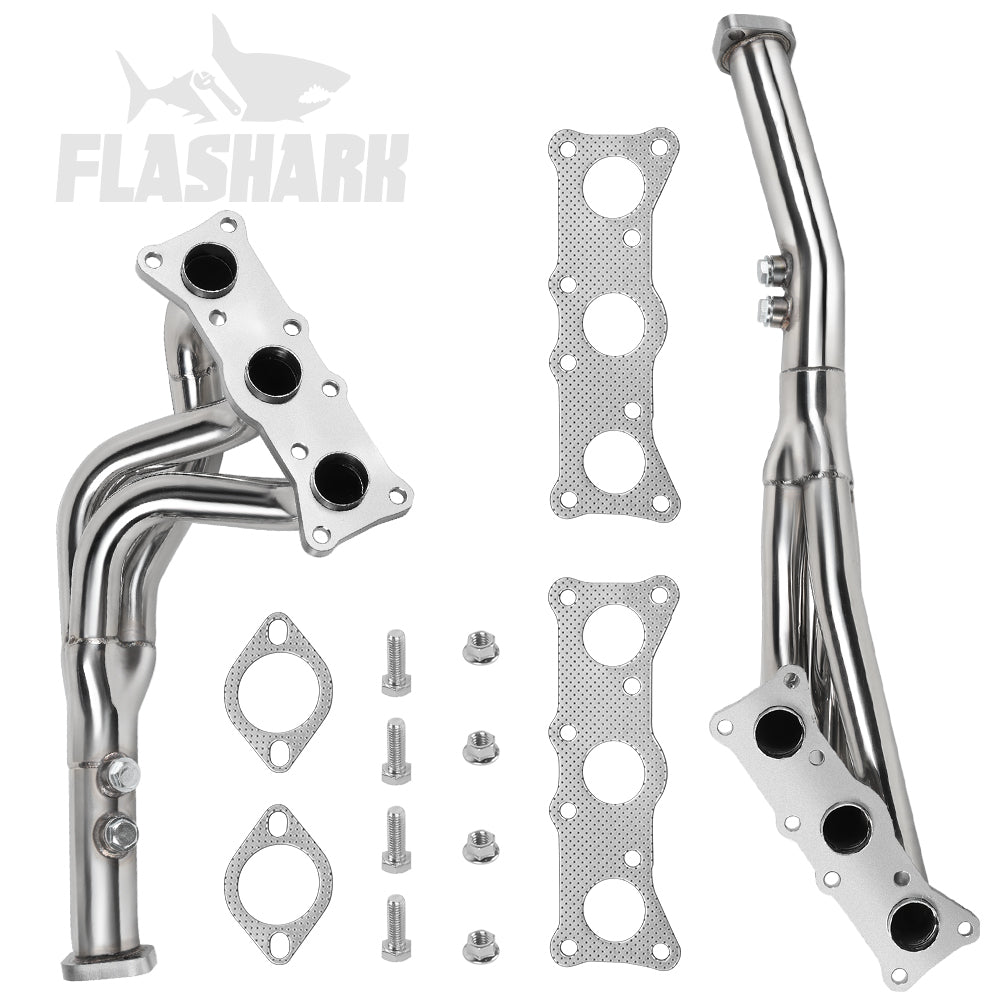

Flashark Exhaust Header for 5.9L Magnum V8

The Flashark 5.9 Magnum header is engineered specifically for 5.9L Magnum V8 applications. Its design closely follows proven exhaust tuning principles for naturally aspirated V8 engines.

To clearly understand how this header integrates with Magnum platforms, the following sections explain fitment coverage and technical specifications.

Flashark Header Fitment Coverage

Proper fitment is essential for both performance and reliability. The Flashark header supports multiple Dodge platforms equipped with the 5.9L Magnum V8.

It fits 1994–2002 Dodge Ram 1500, 2500, and 3500 models, 1997–2004 Dodge Dakota, and 1998–2003 Dodge Durango.

This header is designed for vehicles without EGR systems or with deleted EGR configurations. It is compatible with 2WD applications only and does not fit 4WD models.

Flashark Header Features: How It Works for 5.9 Magnum V8

Each specification directly influences exhaust performance and durability. Understanding these details explains why this header works effectively on Magnum engines.

The 1.5-inch primary tube diameter supports strong exhaust velocity, which is critical for low- and mid-range torque. A 2-inch outlet allows smooth flow into the downstream exhaust system.

A 3/8-inch thick outlet flange improves sealing and resists warping under high thermal loads. Stainless steel construction provides excellent resistance to corrosion and heat cycling, supported by ISO9001-certified manufacturing standards.

How Flashark Headers Improve Power Over Stock Manifolds

Compared to factory cast iron manifolds, tubular headers significantly reduce exhaust backpressure. This improves cylinder evacuation and supports more efficient combustion cycles.

Independent engine dyno testing across comparable naturally aspirated V8 platforms consistently shows horsepower and torque gains when restrictive manifolds are replaced with properly designed headers.

Additional benefits include improved throttle response, a deeper and more aggressive exhaust tone, and modest improvements in fuel efficiency due to reduced engine load.

Is This the Best Header Upgrade for Your 5.9 Magnum?

For drivers searching for the best headers for a 5.9 Magnum, this upgrade delivers a balanced combination of power, efficiency, sound, and durability. It is well-suited for street-driven trucks and SUVs seeking proven performance improvements.

By addressing exhaust airflow limitations at the source, a properly engineered header upgrade remains one of the most effective and reliable performance enhancements available for the 5.9 Magnum V8.