Fitment

1995-2021 Ford Mustang

2020-2022 Ford Explorer

2020-2021 Lincoln Aviator

Flashark Wheel Spacers give your vehicle a more aggressive appearance. When you install Flashark Wheel Spacers, you can increase tire clearance to keep tires from crashing into frame rails and suspension links at the full turn if your vehicle is lifted or larger tires are changed. It can also improve the grip, stability, and handling of the vehicle during driving.

FLASHARK Wheel Spacers are made from CNC-machined 6061 T6 aircraft billet and finished with a Black anodized which is designed to improve aluminum and avoid corrosion. CNC precision machining and professional dimensions ensure the best fitting. The intensity is the same as Alloy Steel.

These Wheel Spacers come with all 4pcs Forged Wheel spacers and open-ended nuts and hardware. The lug Nuts(Bolts) are ISO/DIN 10.9-12.9 grade, using SCM435 steel material with heat treated to avoid breaking.

Features:

Flashark Wheel spacers are used to widen the track width of a vehicle by creating additional space between the wheel and the hub assembly. Some potential benefits of using wheel spacers include:

1. Improved Appearance: Wheel spacers can give your vehicle a wider stance, which can enhance the overall appearance of the vehicle.

2. Better Handling: A wider track width can improve handling by increasing stability and reducing body roll, particularly in high-speed turns.

3. Clearance for Larger Wheels or Brakes: Wheel spacers can create additional clearance between the wheel and brake caliper, allowing for the installation of larger wheels or brakes.

4. Correcting Offset: If your wheels have an incorrect offset, wheel spacers can be used to adjust the positioning of the wheel for better fitment.

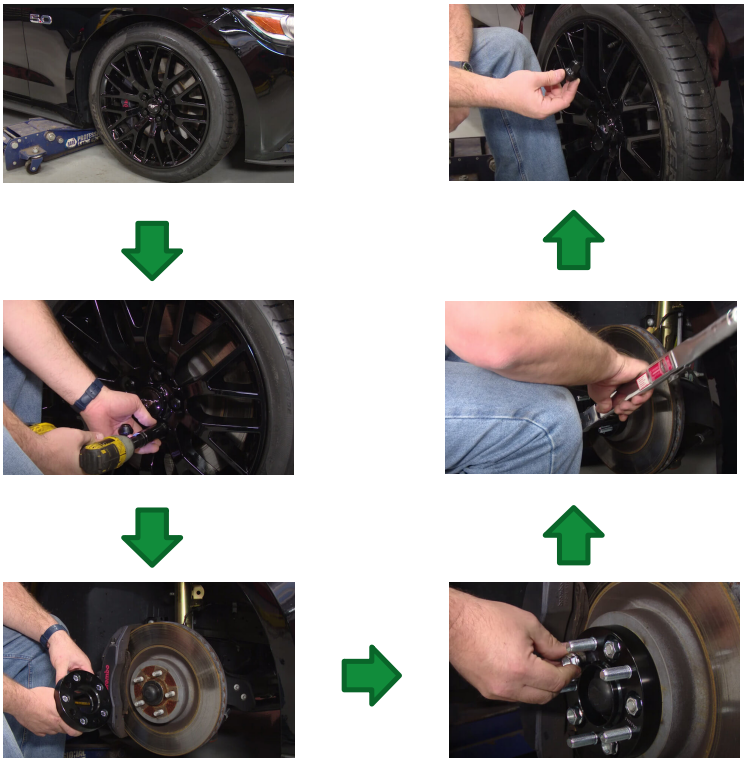

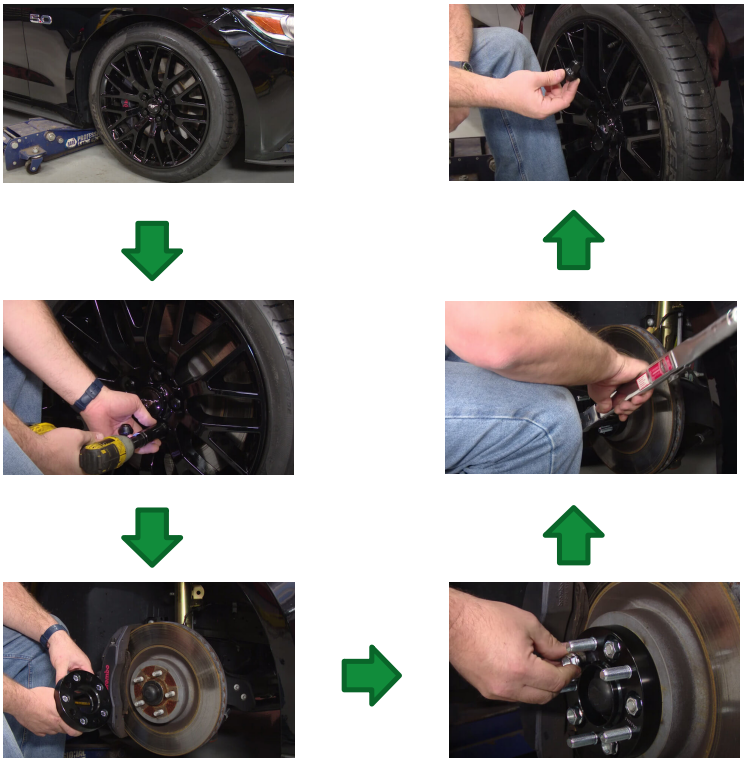

Installation Note:

Step 1: Don't use an impact wrench. Use a jack or lift to raise the vehicle so that the tires are in the air.

Step 2: Remove the wheels/tires

Step 3: Spray degreaser on lug studs

It's not required, but it's a good idea. You want to make sure the wheel spacers are resting on a clean, smooth surface. If there is rust or corrosion, take a wire brush and clean it.

Step 4: Put the wheel spacers in place

Tighten by hand, but do not tighten the bolts. Just snap them all into place and tighten slightly.

Step 5: Tighten the bolts according to the specification

Once all the bolts are in place, use a torque wrench to tighten them to the manufacturer's recommended specifications.

Step 6: Reinstall the wheel onto the assembly/lug studs

Secure and hand-tighten each lug nut before tightening them all the way down. Tighten them in a star pattern to ensure the load is not applied unevenly.